Tungsten Carbide Ball Processing

Processing of Tungsten Carbide Raw Material

When a mixture of powdered tungsten metal and carbon powder are raised to a very high temperature by an arc of electricity, while the whole mass is held in a carbon crucible, there is a complete chemical combination of the two elements to form a big lump of tungsten carbide ( WC ). This lump is crushed several times and then milled to form a fine powder. The powder is screened down to uniform particle sizes. Thus, tungsten carbide raw material is achieved.

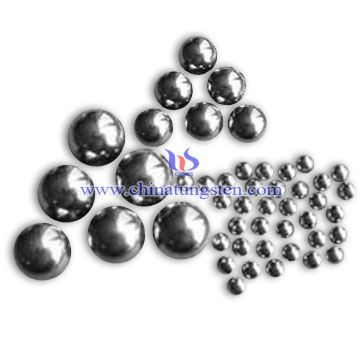

Surface carbide ball through different processing technology and the degree can get tungsten carbide blank balls and tungsten carbide polished balls, Chinatungsten Online is able to make the appropriate tungsten carbide ball processing according to customer needs.

|

Processing of Tungsten Carbide Blank Ball The Tungsten carbide powder and powdered cobalt metal are mechanically mixed to form a uniform combination. To this combination is added a polymer or wax that acts as a mechanical binder in the pre-sintered stage. A carefully measured volume of this combined powder is compressed by a double acting press to form the tungsten carbide ball blank, or pre-form. The binder is removed by placing the preformed parts in a vacuum chamber and raising the temperature. The binder out gasses and is trapped down stream as a liquid. |

|

Next, the combined tungsten carbide and cobalt pre-forms are sintered or fused into a solid mass by heating them to a high temperature in a vacuum or hydrogen atmosphere furnace. Thus, tungsten carbide ball blank is achieved.

Processing of Tungsten Carbide Polished Ball

The metallurgically complete ball blanks are rough ground with course diamond to remove all imperfections from the surface. Using micro size diamond dust, tungsten carbide ball blanks are then finished lapped and polished to final size and microinch roundness with a sub-microinch surface finish.

If you have any other question or inquiry of tungsten carbide ball, please feel free to contact us through the following methods:

Emails:sales@chinatungsten.com

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

More Info>>

Tungsten Carbide Nozzle

Tungsten Carbide Rod

Tungsten Carbide Products

sales@chinatungsten.com;

sales@chinatungsten.com;